The challenge of shipping logistics

Anyone who has ever seen the inside of a dispatch warehouse can certainly imagine what logistics is all about. Basically, material is obtained from a shelf, packed and shipped to the customer. A simple process with the aim of delivering the right item to the customer at the right time and in the correct place.

All this sounds simple, doesn't it?

But this can change rapidly! Let's think of an online retailer who has to ship tens of thousands of packages in a day and has more than 100,000 different items in its assortment. Imagine the flood of paper if he had to print out 50,000 orders a day - the pile of paper would grow 7 metres a day. So it is obvious that this flood of information can no longer be managed without digital support.

Microsoft Dynamics 365 with the WHS (Warehouse) module

With the WHS module, Microsoft has created the basis to map the high demands of the industrial and logistics sector as far as possible with standard functionalities. Additional functions - based on customer requirements - are constantly being added. The module is enormously multi-layered and complex in structure. Thanks to this complexity, customer-specific requirements can be optimally implemented with the standard settings. Of course, the end user does not see these interlocking settings. The employee opens his mobile device and is guided step by step through his daily work without having to know which process steps are being carried out in the background.

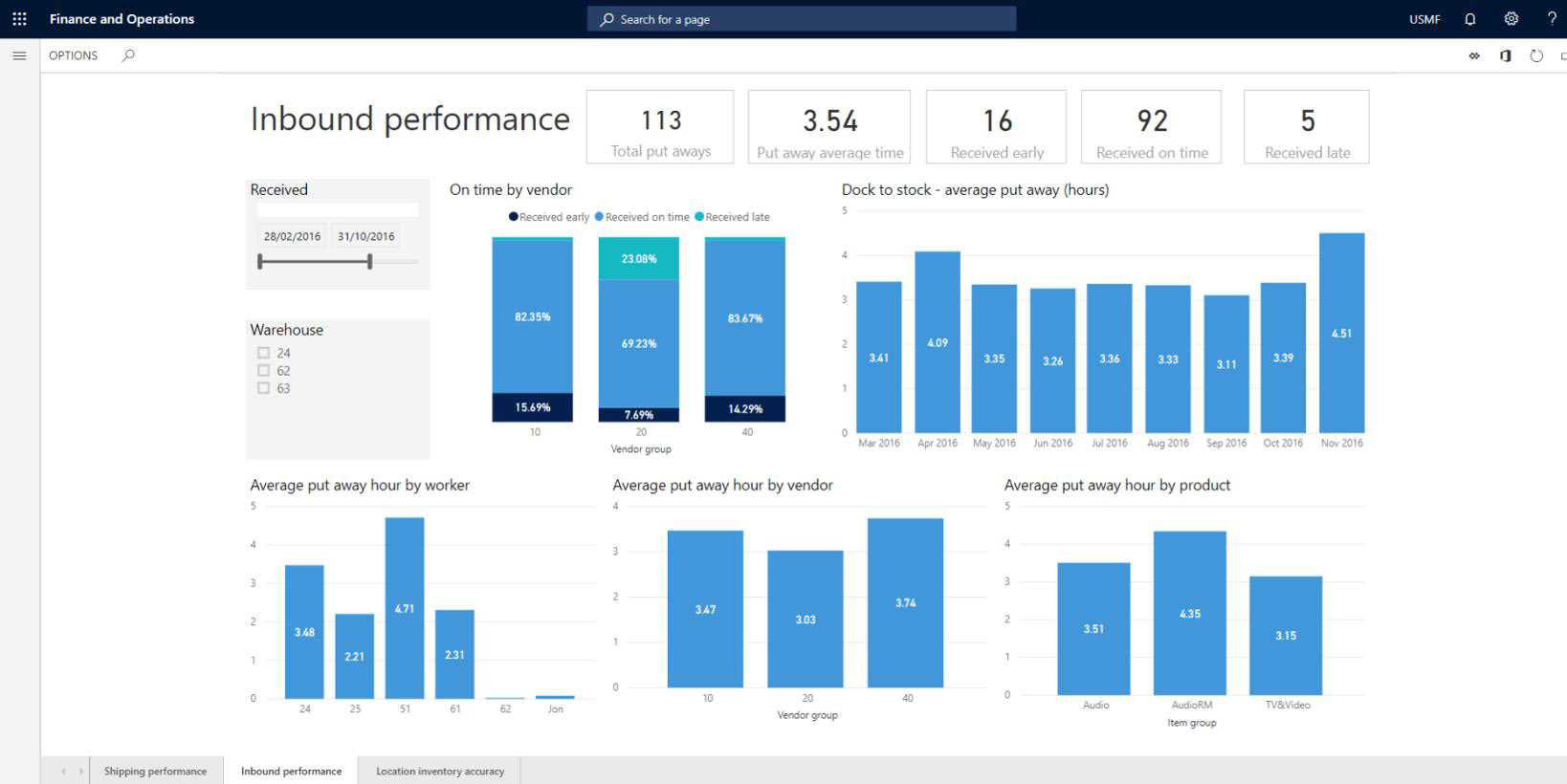

Microsoft offers the possibility of a flexible process structure from incoming goods to warehousing. The logistics processes are completely integrated into production and transport management and offer comprehensive control of inventory levels, storage volumes and their stock limits. Various inventory statuses give users the option of stock control of normal items, serial or batch number-controlled items. Various counting functions are available as standard for inventory security. The shipping process can be set up using different picking strategies; one example is "pick-to-ship", where the shipping items are picked directly into the shipping carton. Furthermore, "cluster picking", in which the picking process can be optimised. Of course, out-of-the-box barcode scanners are supported and the necessary label printers can be triggered by label routing. The module also offers fully integrated quality control as well as tracking of the workers' material handling. With the integration of Power BI (Business Intelligence), business-relevant key figures can be determined. Microsoft is constantly working on new functions to optimise them continuously.

Of course, the process of reaching the required goal requires a lot of time and effort, so that customer requirements can be implemented in the best possible way. With every simplification of processes with the help of WHS, business processes can be optimised sustainably and at the origin. With the higher goal of eliminating any kind of waste.

Have we sparked your interest? We will be happy to advise you!

Further information

Are you interested in this topic? I would be pleased to answer any queries you have.

Andreas Pascutto, Head Sales ERP

andreas.pascutto@!ambit-group.com

+41 79 351 00 38